The future of food is evolving with groundbreaking technology, and 3D meat printing is at the forefront of this transformation. This revolutionary method could change how we consume meat by producing delicious, sustainable, and ethical protein alternatives. Through advanced printing techniques, scientists and food experts are crafting meat products that address both flavor and sustainability concerns.

Curious about how 3D meat printing works? Dive into the latest developments in this field, from the science behind 3D printed meat to the companies pioneering this innovation. Discover the key benefits, such as minimizing environmental impact and enhancing food security. Explore how 3D printed meat might meet the growing demand for sustainable and ethical protein options. Could this technology be the answer to a more responsible future of food production?

How 3D Meat Printing Works

3D meat printing is an advanced process involving four essential stages:

1. Cell Culture

- Cell Isolation: Animal cells—like muscle, fat, or connective tissue cells—are isolated from livestock.

- Cell Proliferation: These cells are then grown in a nutrient-rich environment to multiply.

- Cell Differentiation: The cells are guided to differentiate into specific tissue types, such as muscle or fat cells.

2. Bio-Ink Creation

- Cell Suspension: The cultured cells are suspended in a “bio-ink”—a gel-like medium that provides structural support.

- Biomaterial Selection: Bio-ink is made from biocompatible materials like collagen, fibrin, or alginate, mimicking the natural cellular environment.

- Ink Formulation: The bio-ink is carefully formulated to maintain cell health, ensure printability, and support tissue formation.

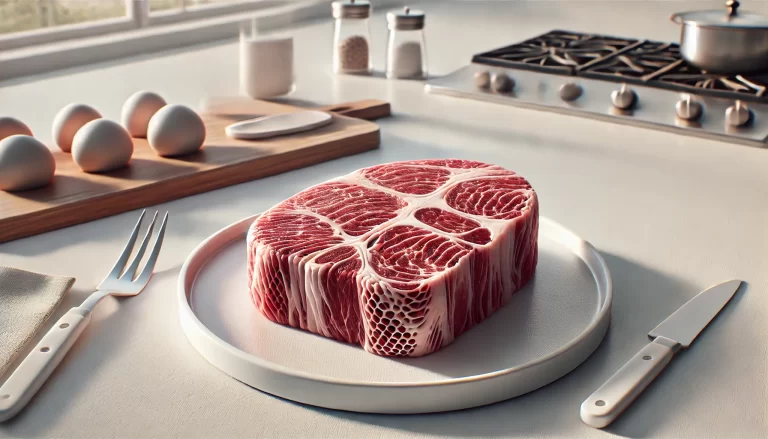

3. 3D Printing

- 3D Printer: A specialized bioprinter deposits the bio-ink layer by layer to form the meat structure.

- Printing Techniques: Techniques like extrusion or inkjet printing allow for creating complex tissue shapes and textures.

- Scaffold Design: Following a digital blueprint, the 3D printer constructs meat products like steaks, burgers, or sausages.

4. Maturation

- Tissue Engineering: The printed meat is placed in a bioreactor, where it matures into full tissue.

- Nutrient Supply: In the bioreactor, essential nutrients and growth factors support cell development.

- Maturation Time: This maturation stage takes several weeks, depending on the type of meat and desired texture.

With each advancement, scientists are improving 3D meat printing to deliver higher-quality, tastier, and more affordable meat alternatives for a sustainable future.

The Cost of 3D Printed Meat

The production costs for 3D-printed meat are currently high, reflecting the complexity of the technology and materials. For example, producing a single cultured meat burger was estimated to cost over $330,000 in 2013.

While costs have declined since, they remain significant. The growth media, essential for cell cultivation, contributes to 55%–95% of total production expenses. Currently, the initial setup for a 3D-printed vegan meat business can range from $50,000 to $500,000.

Potential for Cost Reduction as Technology Advances

As technology progresses, there is substantial potential to lower production costs. Recent research highlights promising developments, including the creation of edible, plant-based bio-ink made from food waste like cereal husks. This cost-effective ink integrates fully into the meat product, offering a sustainable way to reduce expenses in large-scale production.

Furthermore, improvements in bioprinting methods, as well as optimization of supply chains, are anticipated to increase both cost-effectiveness and sustainability. Experts believe that these innovations could make cultured meat a feasible solution to support the world’s growing demand for sustainable protein sources.

Environmental Benefits of 3D Printed Meat

Reduced Carbon Footprint

One of the most impactful benefits of 3D-printed meat is its potential to reduce the carbon footprint of food production. Traditional livestock farming accounts for about 14.5% of global greenhouse gas (GHG) emissions. In contrast, 3D-printed meat, especially when plant-based, can dramatically lower these emissions.

Studies indicate that plant-based alternatives used in 3D-printed meat can reduce GHG emissions by up to 90% compared to conventional meat production. Additionally, these alternatives require up to 99% less water and 95% less land. This reduction in resource use contributes to combating climate change and supports more sustainable food production practices.

Lower Land and Water Usage

3D-printed meat offers considerable advantages in land and water conservation compared to traditional livestock farming. Producing conventional meat is highly resource-intensive; for example, it takes about 1,800 gallons of water to produce just one pound of beef. Additionally, traditional meat production relies on vast land areas for grazing and growing feed.

In contrast, 3D-printed meat, often created using plant-based ingredients or cultured cells, significantly reduces land and water demands. Studies show that producing plant-based alternatives can use up to 99% less water and 95% less land by eliminating the need for extensive farming operations. These processes are conducted in controlled environments that are far more resource-efficient.

Reduced Greenhouse Gas Emissions

Another key benefit of 3D-printed meat is its ability to decrease greenhouse gas emissions. Traditional livestock farming, responsible for around 14.5% of global GHG emissions, produces substantial methane from cattle and involves energy-intensive processes for raising animals.

By comparison, studies show that plant-based alternatives in 3D-printed meat can cut GHG emissions by as much as 90%. This reduction is due to the elimination of large-scale animal farming, which is a major source of methane, and the more energy-efficient production methods used in 3D printing.

Decreased Pollution

3D-printed meat production substantially reduces environmental pollution compared to traditional livestock farming. Livestock operations are significant sources of water, air, and soil pollution, releasing pollutants like ammonia, nitrates, and phosphorus.

In contrast, 3D-printed meat—often using plant-based or cultured ingredients—has a much smaller environmental footprint. Research shows that producing plant-based meat alternatives can reduce water pollution by up to 90% and land pollution by 95%, thanks to the reduced reliance on large-scale farming and its associated waste.

Health and Safety Considerations

FDA Approval and Regulations

The U.S. Food and Drug Administration (FDA) plays a critical role in regulating 3D-printed meat, also known as cultured or cell-based meat. Currently, no cultured animal cell-derived foods are available for sale in the U.S. market. However, the FDA has completed its first pre-market consultation for a cultured meat product, ensuring safety and compliance.

To guarantee these products meet all safety standards, the FDA collaborates with the United States Department of Agriculture’s Food Safety and Inspection Service (USDA-FSIS). Together, they enforce stringent safety requirements under the Federal Food, Drug, and Cosmetic Act.

Regulatory Frameworks

As a “novel food,” 3D-printed meat undergoes rigorous safety evaluations. While the U.S. regulatory framework is still evolving, countries like Singapore are setting precedents. Singapore was the first to approve lab-grown meat, allowing U.S.-based Eat Just to sell lab-grown chicken. This move may pave the way for similar approvals in other nations.

Potential Health Benefits of 3D Printed Meat

- Customized Nutrition: Enables precise nutrient additions, such as omega-3 fatty acids, while reducing unhealthy saturated fats.

- Reduced Cardiovascular Risk: Lower saturated fat content can help decrease the risk of heart disease.

- Lower Diabetes Risk: Plant-based alternatives in 3D-printed meat have been linked to reduced type 2 diabetes risk.

- Decreased Cancer Risk: Reducing red and processed meat consumption can help lower the risk of certain cancers.

- Weight Management: Controlled portions and balanced nutritional content make it easier to manage weight and combat obesity.

Addressing Consumer Concerns and Misconceptions

Consumer concerns must be addressed for 3D-printed meat to gain widespread acceptance. Here’s how companies are tackling common misconceptions:

Taste and Texture

Many worry that 3D-printed meat won’t replicate the taste and texture of traditional meat. Companies like Redefine Meat and Novameat are using advanced bioprinting and plant-based ingredients to mimic the sensory experience of conventional meat. Taste tests suggest promising results, with some consumers unable to differentiate between 3D-printed and traditional meat.

Safety and Health

Questions about safety are common. Regulatory bodies like the FDA are conducting comprehensive evaluations to ensure 3D-printed meat meets safety standards. Unlike conventional meat, cultured meat can be produced without antibiotics and hormones, potentially making it a healthier option.

Ethical and Environmental Impact

Skepticism about the environmental and ethical benefits is another hurdle. Educating consumers on the reduced environmental footprint—lower greenhouse gas emissions, water usage, and land requirements—can address these concerns. Additionally, highlighting the cruelty-free nature of lab-grown meat appeals to ethically conscious consumers.

Cost

High production costs remain a barrier. However, as technology advances and economies of scale improve, costs are expected to drop significantly, making 3D-printed meat competitive with traditional options. Communicating these potential cost reductions and long-term benefits can help align consumer expectations.

Misconceptions About GMOs

Some consumers confuse 3D-printed meat with genetically modified organisms (GMOs). It’s important to clarify that 3D-printed meat is not genetically modified; it is produced using cell cultures or plant-based ingredients.

The Global Landscape of 3D Meat Printing

Several countries are leading the charge in 3D-printed meat research and development, each playing a vital role in advancing this transformative technology.

United States

The U.S. is home to key players in the 3D-printed meat industry, including Upside Foods (formerly Memphis Meats), Eat Just, and Finless Foods. These companies have attracted millions of dollars in investments, enabling them to develop scalable cultured meat products. Their innovative approaches position the U.S. as a leader in the alternative protein market.

Netherlands

The Netherlands has been a pioneer in cultured meat research. Mosa Meat, founded by Dr. Mark Post at Maastricht University, produced the world’s first lab-grown burger in 2013. Today, the country continues to serve as an innovation hub for cultured and 3D-printed meat technologies.

Israel

Israel is a global powerhouse in the alternative protein sector, hosting over 40% of the world’s alternative protein companies. Notable innovators include Aleph Farms, SuperMeat, Steakholder Foods (formerly MeaTech), and Believer Meats (formerly Future Meat Technologies). These companies have secured substantial funding and are driving progress in creating a wide array of cultured meat products.

Singapore

Singapore is at the forefront of regulatory advancements in cultured meat. It was the first country to approve lab-grown meat sales, allowing U.S.-based Eat Just to market its lab-grown chicken. This milestone has solidified Singapore’s status as a key global player in the alternative protein industry.

Notable 3D Meat Companies and Their Innovations

Impossible Foods

- Signature Products:

- Impossible Burger: Features soy leghemoglobin (heme) to replicate the taste and juiciness of beef. Available in over 11,000 grocery stores and 30,000 foodservice outlets.

- Impossible Sausage: Launched in partnerships with Starbucks and Burger King.

- Impossible Beef Hot Dogs: Set to debut in 2024, offering 50% less total and saturated fat compared to traditional hot dogs, with 12 grams of protein per serving.

- Environmental Impact: Produces 84% less greenhouse gas emissions, uses 77% less water, and requires 83% less land than traditional beef production.

Beyond Meat

- Signature Products:

- Beyond Burger (Beyond IV): Features avocado oil and only 2 grams of saturated fat per serving. Available at 20,000 grocery retailers and 10,000 restaurants.

- Beyond Beef: Made from peas, brown rice, red lentils, and faba beans, part of the Beyond IV platform.

- Environmental Impact: Beyond Meat products replicate the taste, texture, and appearance of animal meat while significantly reducing environmental impact.

- Recognition: Named one of 2023’s most innovative brands.

Upside Foods (formerly Memphis Meats)

- Cultured Meat Innovation: Known for pioneering cultured meat products, including beef and chicken meatballs, grown directly from animal cells.

- Environmental Benefits: Cultured meat uses less land, water, and energy, offering a sustainable alternative to traditional meat production.

The Future of 3D Printed Meat

Potential Applications Beyond Traditional Meat Products

3D-printed meat technology has applications beyond conventional meat products, offering innovative solutions across multiple food categories:

- Seafood: Companies like Steakholder Foods are developing 3D-printed seafood, such as lab-grown eel, to combat overfishing and promote sustainable seafood options.

- Poultry: Cultured chicken and turkey from companies like Believer Meats (formerly Future Meat Technologies) and Aleph Farms aim to reduce the environmental impact of poultry farming.

- Plant-Based Alternatives: 3D printing can enhance plant-based products by improving texture and nutrition. Impossible Foods and Beyond Meat are already using advanced techniques to create plant-based burgers and sausages.

- Specialized Diets: 3D-printed meat can be tailored to meet specific dietary needs, like low-sodium or high-protein requirements, benefiting those with health conditions that need customized nutrition.

- Space Food: NASA and other space agencies see potential in 3D-printed food for long-duration missions, as it could provide nutrient-rich, shelf-stable food on demand, essential for space exploration.

Market Predictions and Consumer Adoption

The global 3D-printed meat market is anticipated to grow substantially over the next decade:

- Market Size: Projected to reach $515.4 million by 2030, up from $179.1 million in 2023, with a compound annual growth rate (CAGR) of 16.3%.

- Regional Dominance: North America is expected to lead, capturing 36% of the market, followed by Europe at 27%. The Asia-Pacific region is forecasted to grow rapidly due to rising consumer awareness and disposable incomes.

- Product Segments: 3D-printed chicken is expected to be the top revenue-generating segment, with a CAGR exceeding 16% from 2023 to 2033.

Consumer Adoption Insights

Consumer adoption of 3D-printed meat is influenced by perceived benefits, environmental impact, and health considerations:

- Consumer Interest: In a recent survey, 39% of Australians reported actively reducing their meat consumption, and 38% were open to plant-based meat substitutes.

- Market Growth: U.S. demand for meat alternatives surged by 264% during the COVID-19 pandemic. Redefine Meat predicts this category could reach $140 billion annually by 2030.

- Perceived Benefits: Health, sustainability, and dietary alignment are factors that make consumers more likely to embrace 3D-printed meat.

Ethical Considerations and Future Challenges

Animal Welfare: A key ethical benefit of 3D-printed meat is the potential to eliminate animal slaughter, significantly reducing animal suffering. Cultured meat is produced from animal cells without the need for conventional livestock farming.

Environmental Impact: Producing 3D-printed meat has a much smaller environmental footprint. Compared to traditional meat production, it can reduce greenhouse gas emissions by 90%, water use by 96%, and land use by 99%.

Health and Safety: Ensuring that 3D-printed meat is safe for consumption is a primary concern. Regulatory bodies like the FDA are working to establish standards for cultured meat to guarantee consumer safety.

Future Challenges of 3D Printed Meat

- Regulatory Approval: The regulatory landscape for cultured meat is complex, with varying standards across countries. Obtaining approvals can be a lengthy process.

- Consumer Acceptance: Overcoming the “yuck factor” and educating consumers about the safety and benefits of 3D-printed meat is essential for widespread adoption.

- Technological Advancements: Achieving the desired texture and taste of traditional meat remains a challenge. Ongoing research and development aim to improve the sensory quality of cultured meat.

- Cost: Production costs for 3D-printed meat are currently high. Scaling production to achieve cost parity with traditional meat is vital for commercial viability.

- Sustainability: Although 3D-printed meat has a lower environmental impact, maintaining sustainable production as the industry scales is crucial.

FAQs About 3D Printed Meat

Can 3D printers create meat?

Yes, 3D printers can create meat. This technology uses animal cells to produce meat products, eliminating the need for traditional livestock farming and offering a sustainable approach to meat production.

Which companies are leading in 3D meat printing?

Several companies are pioneering 3D meat printing technology. Notable examples include Upside Foods (formerly Memphis Meats), Believer Meats (formerly Future Meat Technologies), and Aleph Farms. These companies are actively developing and refining 3D-printed meat products.

Is 3D printed meat healthy?

While still in early development, 3D-printed meat has the potential to be as healthy as traditional meat. It can be tailored to meet specific nutritional needs and produced without hormones or antibiotics. However, ongoing research is essential to fully understand its long-term health effects.

What are the benefits of 3D printed meat?

3D-printed meat offers numerous benefits. It’s more sustainable, requiring less land, water, and resources. It’s also more ethical, as it eliminates the need for animal slaughter. Additionally, 3D-printed meat can be customized for specific dietary preferences or nutritional requirements.

Final Thoughts

The rise of 3D meat printing represents a significant advancement in food technology. This innovative approach could reshape meat production and consumption by addressing key global issues like food security, environmental impact, and animal welfare. As research progresses, 3D-printed meat may become a widely accepted and sustainable food source.

It is crucial, however, to carefully consider the ethical and regulatory implications of this emerging technology. By prioritizing responsible innovation and sustainable practices, we can harness the potential of 3D meat printing to create a more sustainable and equitable food system.